FoamTronic is an electronic foam mixing system which very accurately mixes foam concentrate and water, based on the actual firewater demand of the system.

ELECTRONIC FOAM MIXING TECHNOLOGY

- Smart technology;

- Environmental friendlyk;

- High accuracy;

- No pressure loss;

- Self-diagnostics.

FoamTronic allows system performance to be regularly tested without mixing foam and water, thus avoiding environmental concerns and depletion of valuable foam stocks.

Foam proportioning systems rely on the accuracy of the percentage mixing ratio of foam concentrate to water, with the FoamTronic technology this accuracy can be controlled to finite levels and will automatically adjust to changes in system demand.

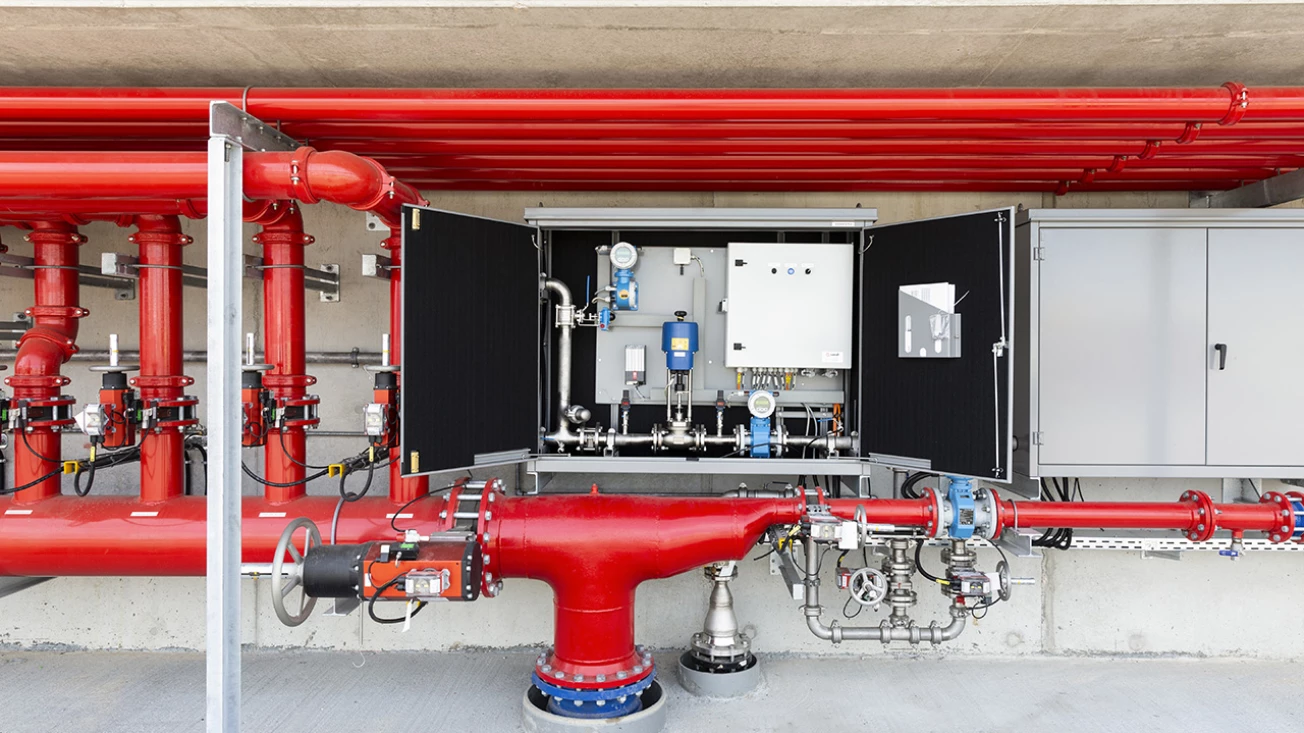

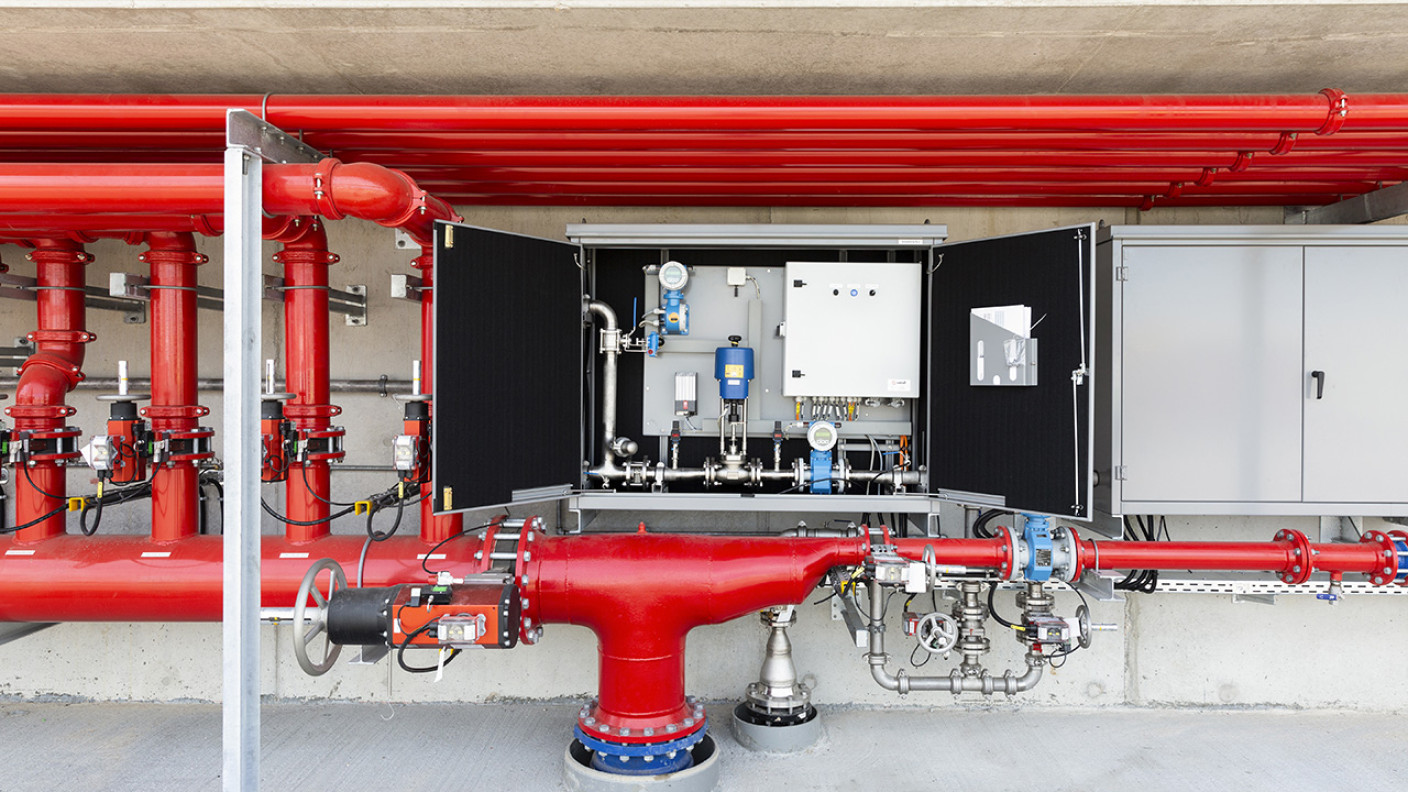

An advantage of the FoamTronic is that there is no pressure loss in the water supply towards the extinguishing systems. The FoamTronic can be installed close to the foam storage or on remote locations where multiple FoamTronic systems can be used on site using a centralized foam storage system.

FOAMTRONIC CABINET

FoamTronic is designed for the harshest environments. The cabinet is manufactured from stainless steel and powder coated to ensure maximum corrosion protection. The complete assembly is preassembled using high quality components. Options such as cabinet heating and insulation are available.

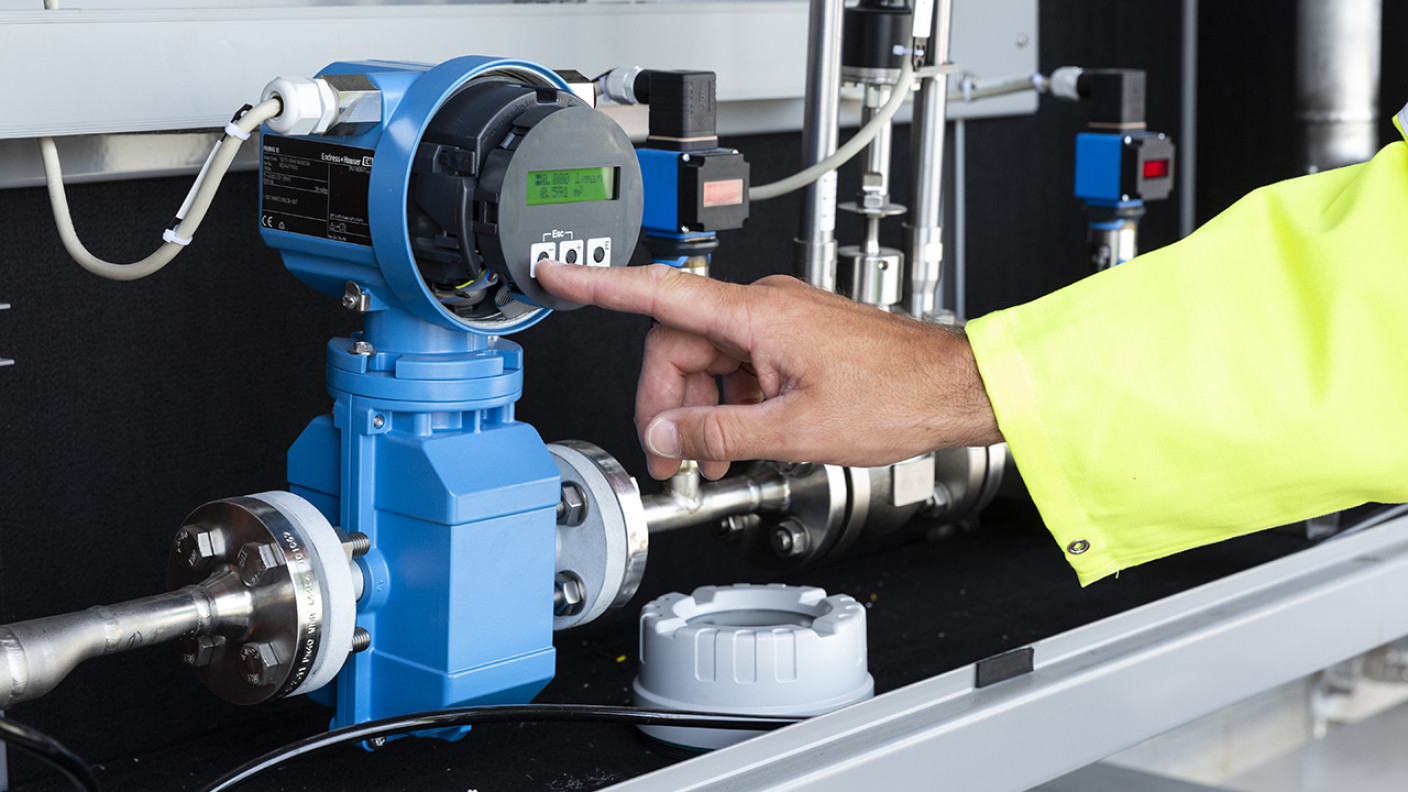

User interface

A touchscreen is integrated into the front panel of the controller cabinet. This intuitive graphic user interface allows a user to view system parameters and diagnostics. All process values, alarms and events are recorded during normal operation and testing of the system.

System capacity

The FoamTronic can be adjusted to match project specific requirements and components will be selected to ensure optimum operation. The system capacity depends on the allowable pressure drop over the flow control valve which is sized to suit each application. Examples of system capacity are indicated for 1% and 3% mixing ratios.

The FoamTronic system up to DN50 is standardized into the same cabinet, larger sizes are available and will be custom built. Other flow rates are available up on request.